Newsletter

Stay connected

Stay informed with our newsletters! Get the latest software release news, dive into cutting-edge fatigue analysis with FEMFAT, discover exciting events and training opportunities and explore captivating case studies. Plus, we're here to answer your FAQs. Join us and explore the world of engineering excellence!

Subscribe to our Newsletter

Newsletter 32/2024

FEMFAT 2024.1; Trainings & Events; FEMFAT MELCOM; HARMONIC in FEMFAT inside Ansys; FAQs

FEMFAT Release News

We are excited to announce the latest updates and enhancements in FEMFAT.

In this article, we will highlight the key features and improvements that have been introduced in the recent release FEMFAT 2024.1.

These updates are aimed at further enhancing the efficiency and accuracy of fatigue analysis, as well as expanding the capabilities of FEMFAT in various areas.

Performance Improvements

In FEMFAT 2024, a completely new, thread-based parallelization was introduced in ChannelMAX. With the current release, this modern form of parallelization is also available in the TransMAX and SPECTRAL modules.

Additionally, the ability to specify the number of workers/threads as a start parameter for FEMFAT provides users with greater control and flexibility in optimizing their resources.

The pro file now also includes the output of the used workers/CPUs, allowing for better monitoring and analysis of the computational resources utilized.

FEMFAT MELCOM

Allow us to introduce FEMFAT MELCOM, our brand-new electronic simulation software!

It features three modules to address typical challenges in PCB (printed circuit boards) development:

- solder joint fatigue analysis

- chip crack analysis

- thermo-mechanical analysis

Please refer to the technical article in this newsletter edition for deeper insights.

VISUALIZER

The VISUALIZER now allows users to easily incorporate screenshots into presentations. By simply dragging and dropping screenshots into Power Point, Word or Excel, users can seamlessly integrate visual representations of their analysis results, making it easier to communicate and share findings with colleagues and stakeholders.

The list of node characteristics displayable by VISUALIZER has been expanded by General Surface Treatment Factor, Boundary Layer Thickness, Surface Residual Stresses, Input for SDAS, and Fiber Orientation (1st eigenvalue).

Furthermore, the VISUALIZER module now offers the ability to synchronize groups with fps files, improving the collaboration and data management capabilities within FEMFAT.

Material Generator

New material classes have been introduced for titanium, stainless steel, forged steel, ausferritic ductile iron, nitrided steels and highest strength steels.

Handling

Group handling has been enhanced to automatically complete element groups when reading geometry. This feature simplifies the modeling process and saves time by automatically generating complete groups based on imported geometry.

The identification of local extrema has been enhanced to include WELDs and SPOTs, providing users with a more comprehensive analysis of critical locations. In addition, this functionality has also been incorporated into the VISUALIZER, allowing for a more intuitive and visual representation of the identified local extrema.

Interfaces

ChannelMAX now offers a new interface to Abaqus dat-File for load history data from a modal transient analysis.

Additionally, users can now read shell thickness from h3d files.

The NASTRAN bulk (Optistruct) interface has been improved to support components from Hypermesh comments as properties.

WELD

In the WELD module, the introduction of inclined elements allows for more accurate modeling and analysis of welded structures, ensuring another way of realistic fatigue predictions for welded components.

SPECTRAL

The SPECTRAL module now offers both logarithmic and linear (as well as mixed representations) of the equivalent stress PSD curve, providing users with more flexibility in analyzing and interpreting the stress distribution.

These latest updates and enhancements in FEMFAT are aimed at empowering users with advanced tools and features to ensure more accurate and efficient fatigue analysis.

Please note that the information provided above is an overview and does not include all the details.

For more information, please refer to the official FEMFAT release notes.

FEMFAT - Trainings & Events

Check out our event overview!

| Jan, 29 - 30, 2025 | DVM Betriebsfestigkeit – Numerische Simulation in der Betriebsfestigkeit – Darmstadt (Germany) |

| May, 14 -15, 2025 | Magna ECS Simulation Conference – Waidhofen / Ybbs (Austria) |

| May, 19 - 22, 2025 | NAFEMS World Congress 2025 – Salzburg (Austria) |

| May, 19 - 21, 2025 | EVTeC 2025 – Yokohama (Japan) |

Check out our training overview!

Standard Training (online)

Feb, 4 - 7 , 2025 – every day CET 08.30 – 12.30

Mar, 10 - 13, 2025 – every day CET 13.00 – 17.00

June, 3 - 6, 2025 – every day CET 08.30 – 12.30

July 8 -11, 2025 – every day CET 08.30 – 12.30

Advanced Trainings (online)

| MAX | Feb, 11 - 12, 2025 – every day CET 08.30 – 12.30 |

| SPECTRAL | Mar, 25 - 26, 2025 – every day CET 08.30 – 12.30 |

| Material | June, 11 - 12, 2025 – every day CET 08.30 – 12.30 |

| Non Metal Fatigue | July, 15 - 16, 2025 – every day CET 08.30 – 12.30 |

FEMFAT MELCOM Software

1. FEMFAT MELCOM Software

The trend towards electrification of vehicles requires an increased number of electronic components which need to withstand different environmental influences, like thermal, vibration and static loading. In the following, vibrational loads, as specified in different standards (e.g. LV124) [1] will be treated. Those standards define stochastic, deterministic vibration profiles as well as shock loads that an electric drive must endure during a test scenario to guarantee the vehicles function. An essential part of the e-drive is the inverter, which includes printed circuit board assemblies (PCBA). These consist of the printed circuit board (PCB) and different surface mounted devices (SMD), which are connected by solder joints. The mechanical integrity of these joints is essential for the function of the inverter. Therefore, it must be ensured that these solder joints can endure the specified mechanical loads. Predicting possible damages in an early design phase by virtual testing can save additional design loops as well as physical testing and therefore development costs.

For that reason, FEMFAT MELCOM Software has been developed for the assessment of electronics. This software uses ODB++ data as input for automated FE-modelling processes and leads through multiple steps from pre- to postprocessing including fatigue analysis with FEMFAT. Figure 1 shows the graphical user interface and moreover an automatically generated solder joint of the included database. Of three available processes Solder-Joint Fatigue, Chip-Crack and Thermo-mechanical the SolderJoint Fatigue process will be described in detail.

Figure 1: FEMFAT MELCOM Software graphical user interface (GUI)

2. Simulation process

The vibration fatigue analysis of solder joints requires an accurate finite element model of each individual solder joint. Due to the large number of SMDs on an Inverter PCB (up to thousands) it would be impractical to model all solder joints manually, thus the model generation needs to be automated. In the simulation process this is achieved by automatically placing simplified finite element SMD models (using shell and beam elements) on a shell model of the PCB. The solder joint which represents the connection between PCB and SMD, are included via sub-models.

Figure 2: Simulation process

The resulting overall PCBA model is then used to conduct a modal reduced steady state dynamic analysis. In a subsequent FEMFAT analysis, the damage can be automatically assessed. This is achieved by mapping the frequency-dependent movement of each solder joint onto the detailed sub-model. For more details see [2].

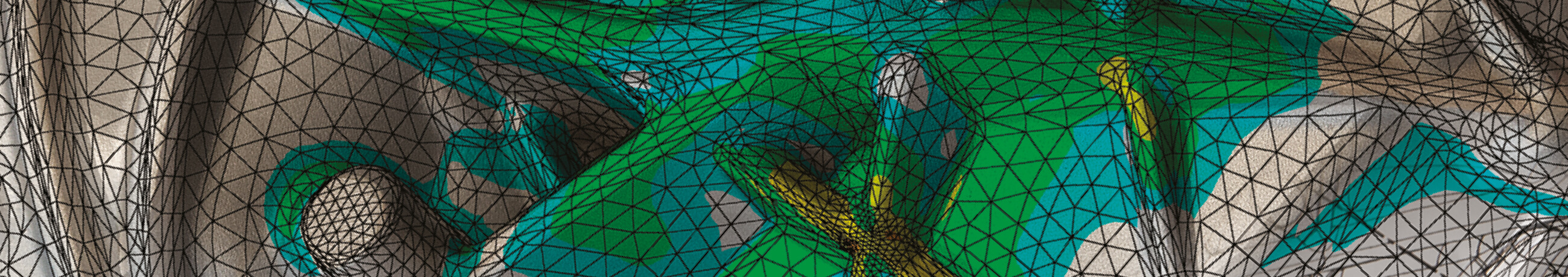

3. Finite-element model

To make this process efficient, a database for SMDs is used every time an overall PCBA model is built (see Figure 1). For each SMD package type this database contains a simplified model (consisting of beams and shells) and a detailed solder joint model (solid-meshed).

Overall model: When modelling a new PCBA the PCB itself usually is modelled with shell elements. Nevertheless, the inhomogeneous material distribution due to the complex composition of layers, traces and drills has to be considered. An automated process takes the coordinate information of every finite element of the meshed PCB and maps it over the layer composition retrieved from ODB++ export (from e-CAD). For every element the enclosed materials are homogenized into one material which gets assigned to the corresponding finite element of the PCB.

Subsequently all SMDs are automatically placed onto the PCB from the database using the Pick&Place export (from e-CAD). The beams of the simplified SMD models, representing the pins, are connected with ABAQUS substructure elements with two interface nodes carrying the reduced stiffness matrix of the corresponding detailed solder joint model (see Figure 2) [3].

Figure 3: Structure of FE model generation

Simplified SMD model: If a new SMD package needs to be added to the database its geometry data has to be specified from the datasheet. An algorithm takes this data as an input and automatically generates a simplified SMD model using beam and shell elements and adds it to the database.

Figure 4: Left: solder joint sub models, right: simplified SMD models

Detailed solder joint model: The shape of the solder joint depends on the solder-type (see Figure 3) as well as the size of the solder pad. After specifying this data, the automated process utilizes a parametric CAD model as well as a parametric solder joint FE-model of the corresponding solder-type. The solder meniscus shape is automatically calculated and takes physical parameters like surface tension during the soldering process and gravity into consideration [4]. The resulting geometry of the solder meniscus is imported into the FE-preprocessor where it is automatically meshed and stored in a database similar to the simplified SMD model.

4. Fatigue life prediction

A modal analysis followed by a frequency response analysis needs to be carried out for the overall model. The nodal displacements of both interface nodes from each substructure element are exported for every frequency and all degrees of freedom. Additionally for each new detailed solder joint model in the database a static stress analysis with unit-displacements is conducted in all 6 degrees of freedom separately for both interface nodes of the sub-model. Both results together form the input for a solder joint fatigue calculation.

Figure 5: Durability assessment process

Fatigue assessment: Stochastic load profiles like PSDs can be used as a direct input in FEMFAT spectral. If a deterministic signal needs to be calculated (e.g. sine sweep or mechanical shock), the software tool Harmonic is used to generate the load-time history from the frequency response behavior which is the input for a subsequent FEMFAT ChannelMax analysis. The material data (ultimate strength, yield strength, S-N curve, etc…) for the FEMFAT analysis is based on literature like [5]. For each solder joint an analysis job is automatically created and calculated. The maximum damage value of each solder joint is exported into one overall result file for further post processing.

5. FE - post processing

In the postprocessor the overall result file can be loaded to the overall model of the PCBA. The maximum damage value of each solder joint is assigned to the corresponding sub-structure element. This allows a quick identification of problematic areas on the PCBA. For the critical solder joints the result files from FEMFAT can be reviewed to receive detailed information about the location of the highest damage on the solder joint as well as critical frequencies and load directions.

Usually, movement of the critical SMD is sufficient improvement to mitigate the occurring damage. Furthermore, application of additional mounting points or adhesives on the PCB can reduce the overall mobility of the PCBA and therefore lower the solder joint damage values.

6. Conclusion

Using automatization and different sub-structuring and sub-modelling techniques FEMFAT MELCOM Software was developed to calculate the vibration fatigue of each solder joint on a PCBA time and cost efficiently for deterministic and stochastic load cases. Application of this simulation process allows the identification of critical solder joints in an early design phase where improvements can prevent costly defects during later tests or even during operation.

Even though this description concentrates on the vibration fatigue calculation of solder joints, other loading types also have to be considered. Especially for thermal loads as well as pretension loads during assembly automated analysis processes exist. All those methods are available in FEMFAT MELCOM Software that assist an efficient assessment of PCBAs [6].

7. References

[1] | Volkswagen Aktiengesellschaft, LV 124, Wolfsburg, 2013. |

[2] | H. Ziegelwanger and W. Hinterberger, Fatigue analysis of solder-joints for vibration and shock, St. Valentin: MAGNA Powertrain, 2021. |

[3] | Dassault Systemes, SIMULIA User Assistance 2020, Dassault Systemes, 2020. |

[4] | K. A. Brakke, "The Surface Evolver," Experimental Mathematics, vol. 1, no. 2, pp. 141-165, 1992. |

[5] | N. Barry, Lead-free Solders for High-Reliability Applications: High-Cycle Fatigue Studies, University of Birmingham, 2008. |

[6] | Engineering Center Steyr, "CAE/Simulation: NVH,". Available: https://engineering.mpt.magna.com/engineering/nvh |

ACT Extension “FEMFAT inside Ansys”: Introducing the Harmonic Tool

We are excited to announce the addition of the Harmonic tool to our extension “FEMFAT inside Ansys”, enhancing your capabilities in fatigue analysis under harmonic loading conditions. This powerful tool allows for the evaluation of vibrational fatigue life under various loading conditions through a streamlined workflow. The loading conditions include constant sine signal, linear and logarithmic sine sweep, as well as arbitrary signals from table definition or load history files. This approach uses modal stresses and modal transfer functions. Consequently, it is computationally very efficient and enables the consideration of resonance effects in the fatigue analysis.

As a prerequisite, the workflow of Modal analysis → Harmonic analysis → ChannelMAX has to be defined (s. figure 1).

Figure 1: Input workflow for Harmonic

With this suitable workflow, the “Harmonic Tool Definition” button becomes visible, enabling easy configuration. Users can then select the “Harmonic Tool based on Modal analysis” option and choose the relevant output load history files.

Figure 2: Channels table with Harmonic Tool

The Harmonic Tool offers various definition options via a custom GUI and performs harmonic evaluation before the FEMFAT analysis. The resulting output file is seamlessly integrated into the “Solution information” object, ensuring a smooth and efficient analysis process.

Figure 3: Harmonic Tool definition window

Experience the enhanced efficiency and reliability in your fatigue analysis with our newly integrated Harmonic tool, and take your engineering simulations to the next level!

Frequently Asked Questions

FAQ 1: How does the automatic assignment of load history data work?

Check Category "Module max" for ANSWER

FAQ 2: In WELD, what does the option “Use Assessment Distance Zero for Root” mean and when is it recommended?

Check Category "Module weld" for ANSWER